Taylor Machinery Co.

The Full Grip - 52 / 96 Combi Plate / Rectangle Zero Point Plate

The Full Grip - 52 / 96 Combi Plate / Rectangle Zero Point Plate

Couldn't load pickup availability

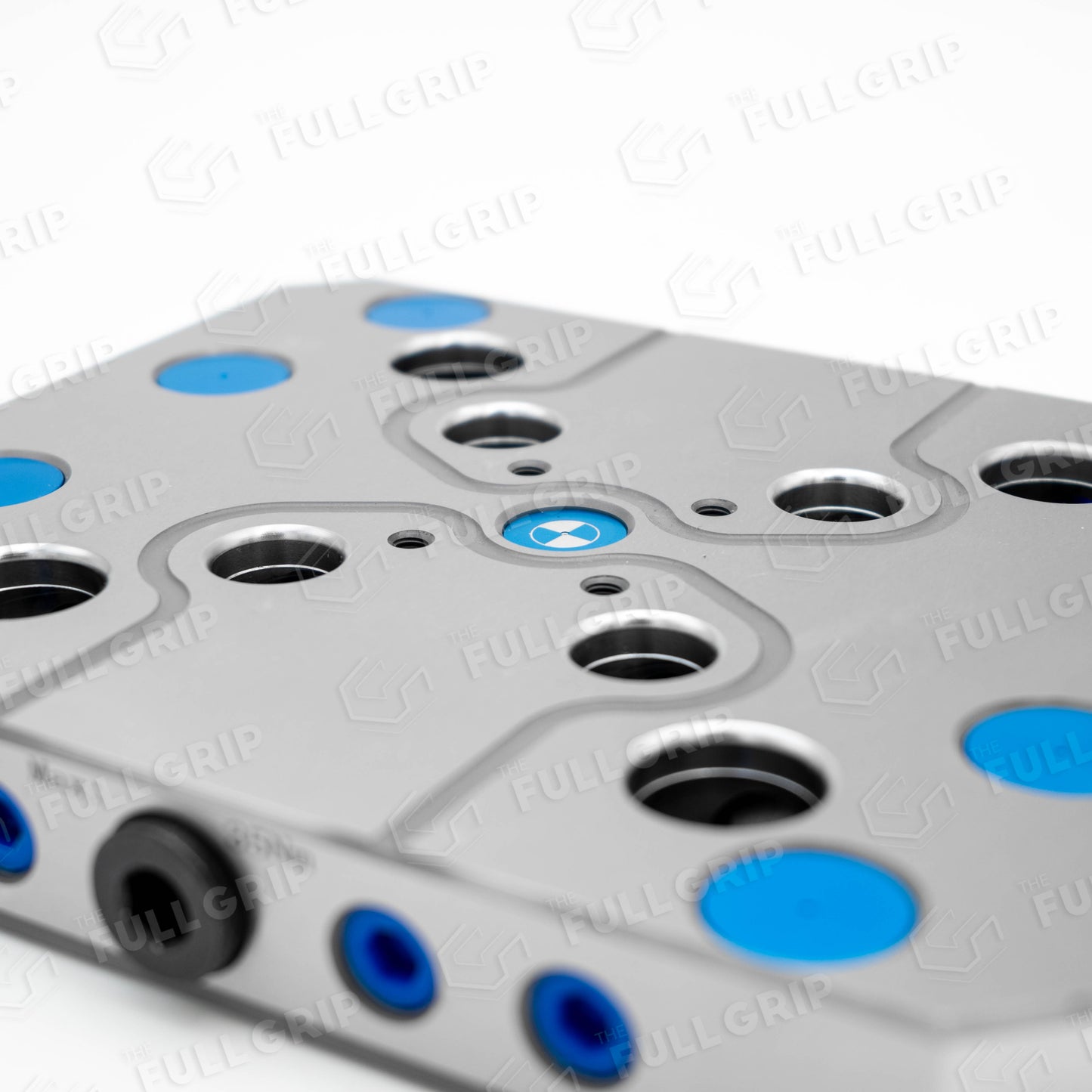

The Full Grip – 52 / 96 Combi Plate / Rectangle Zero Point Plate

Dual-System Zero-Point Base Plate for Maximum Flexibility and Control

When adaptability meets precision, you get The Full Grip – 52 / 96 Combi Plate / Twin Base. Designed for workshops that run both 52 mm and 96 mm zero-point systems, this hybrid base plate gives you unmatched flexibility in your fixturing setup — perfect for shops doing high-mix work, quick changeovers, or transitioning between light and heavy-duty clamping.

Featuring two integrated zero-point stations — one 52 mm and one 96 mm — side by side, this twin base allows operators to mount different fixtures or parts simultaneously. Whether you're clamping small precision components or larger, heavy-duty workpieces, The Full Grip gives you the power to do both without compromise.

Key Features:

-

Dual Interface System:

One plate, two standards — use both 52 mm and 96 mm pull-stud systems on the same base without retooling or downtime. -

Twin Base Format:

Two clamping zones for parallel setups — ideal for running mixed jobs, splitting workflows, or simply staying ready for anything. -

Hardened Tool Steel Construction:

Built from premium-grade tool steel (min. 56 HRC) to handle repeated clamping cycles, high loads, and harsh shop conditions. -

Precision Ground Surfaces:

Top and bottom faces are ground flat for tight repeatability (≤ 0.005 mm) and easy integration into any CNC setup. -

Quick Mounting:

Comes pre-drilled for bolt-down installation on machine tables, tombstones, subplates, or pallets. -

Maximum Productivity:

Speeds up fixture changes, reduces idle time, and allows flexible part scheduling on one base plate.

Technical Specifications:

-

Zero-Point Interfaces: 1x 52 mm + 1x 96 mm

-

Plate Format: Twin base (side-by-side layout)

-

Material: Hardened tool steel (min. 56 HRC)

-

Surface Finish: Ground

-

Repeatability: ≤ 0.005 mm

-

Mounting: Pre-drilled bolt holes

-

Applications: CNC machining centres, rotary tables, pallet changers, automated work cells

DIMENSIONS:

192 × 156 × 27 mm

Share